Synthetic Emerald

Introduction

While synthetic sapphire and ruby hit the market in large quantities by 1907 thanks to the flame fusion technique pioneered by French chemist Verneuil, creating synthetic emerald proved much trickier. That method just didn't cut it for emeralds, and it wasn't until about 30 years later that an American chemist named Carroll Chatham cracked the code for commercial success.

Carroll Chatham's Early Experiments

Chatham was a sharp-minded chemist who got hooked on synthetic gems young. Picture this: as a teen, he attempted to whip up diamonds in his garage lab by mixing graphite into molten iron. To cool it fast, he dunked the whole thing in liquid nitrogen - boom! The explosion shattered windows all over his San Francisco neighborhood.

After some strong words from his dad and the local police, he shifted gears to emerald crystals. By 1930, he'd managed to grow colorless beryl crystals, and then in 1935, he produced his first real emerald - a one-carat beauty now on display at the Smithsonian Institution.

Breakthrough in Emerald Synthesis

The Verneuil approach flopped for emeralds because they're aluminum beryllium silicate tinted by chromium, and getting all those elements to melt together is a nightmare - some vaporize before others even liquify.

The Flux Method Explained

Chatham's genius move was using a special solvent known as flux, a mix of chemicals like lithium oxide, molybdenum oxide, and vanadium oxide that remains liquid at scorching temperatures. His secret flux formula made it possible to blend all the ingredients properly. He'd hang tiny seed crystals in the hot flux to kickstart the growth of new ones. Growing stones big enough to sell could take up to a year in that setup.

Superiority of Synthetic Emeralds

In certain ways, Chatham's created emeralds outshine the natural versions. Natural emeralds often come loaded with inclusions and cracks that reduce durability, making them less tough despite their solid hardness rating of 8 on the Mohs scale. Chatham's emeralds skip all those flaws entirely.

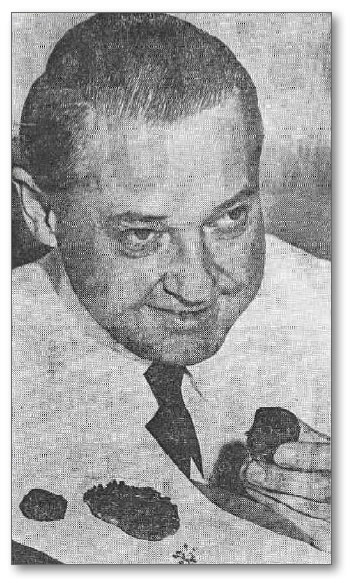

Legacy and Business

Chatham wasn't just a lab whiz; he had business smarts too. He founded a company to market his created emeralds and expanded the tech to produce rubies, alexandrites, plus blue and orange sapphires. He passed away in 1983, but his son kept the operation going. Not long after, the company achieved his lifelong goal of lab-grown diamonds.

Frequently Asked Questions

Who invented the commercial method for synthetic emerald?

Carroll Chatham, an American chemist, developed the successful flux method in the 1930s.

Why couldn't the Verneuil method be used for emeralds?

It was hard to melt all the components together without some evaporating, due to emerald's complex composition of aluminum beryllium silicate colored by chromium.

How long does it take to grow a synthetic emerald using the flux method?

It can take up to a year to produce marketable stones.

Are synthetic emeralds more durable than natural ones?

Yes, they lack the inclusions and fractures common in natural emeralds, making them more resilient despite the same hardness level.

What other gems did Carroll Chatham's company produce?

The company expanded to create rubies, alexandrites, blue and orange sapphires, and eventually lab-grown diamonds.